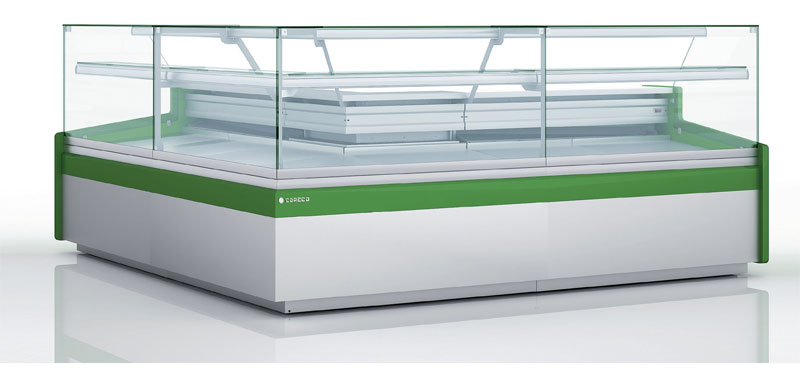

- Exterior and interior steel sheet prepainted

- Exposure and protection evaporator in epoxy finish plate

- Sides polystyrene injected, 40 mm thickness

- Worktop in laminate, melamine finish

- Lacquered aluminum profiles

- Intermediate glass shelf, optional

- Toughened curved glass hinges forward, two versions available

- Lighting Standard on top surface

- Isolation of polyurethane, density 40 Kg / m³, low GWP and zero ODP effect

- Refrigerated under storage with doors 440x270free,

- Static evaporator

- Condensation ventilated

- Electronic temperature control

- Temperature Indicator

- Automatic Defrost

- Climate class 3 (25 ° C 60% RH) regime M1

- M1 product temperature -1 / +5 ° C UNE-EN ISO 23953-2:2006

Here you can find a small overview of our Display products available.

If you are unable to find the catering equipment that you’re looking for, be sure to get in touch with us by filling the form on our Contact Page.

We are certain that we can meet all your Catering Equipment & Display requirements, no matter what they are!

-

-

- Exterior and interior steel sheet prepainted

- Exposure and protection evaporator in epoxy finish plate

- Sides polystyrene injected, 40 mm thickness

- Worktop in laminate, melamine finish

- Lacquered aluminum profiles

- Intermediate glass shelf, optional

- Toughened curved glass hinges forward, two versions available

- Lighting Standard on top surface

- Isolation of polyurethane, density 40 Kg / m³, low GWP and zero ODP effect

- Refrigerated under storage with doors 440x270free,

- Static evaporator

- Condensation ventilated

- Electronic temperature control

- Temperature Indicator

- Automatic Defrost

- Climate class 3 (25 ° C 60% RH) regime M1

- M1 product temperature -1 / +5 ° C UNE-EN ISO 23953-2:200

-

- Interior and exterior finish in plastic coated steel - Display area and counter in stainless steel AISI-304 - Smooth deck for display area, stepped at same price - Sides in ABS injected, 40 mm thick - Standard decoration: bottom frontal and sides in light grey, top frontal in stainless steel - Anodised aluminium profiles - Front rubber bumper - Toughened curved glass hinges forward - Glass shelf non refrigerated - Standard lighting: top worktop and shelf - 40 Kg/m³ density polyurethane insulation, zero ODP and GWP - Refrigerated under storage with doors 440x270 - Static evaporator, ventilated as optional - Ventilated condensation and automatic evaporation as standard (only models with condenser unit) - Electronic temperature controller - External thermometer - Auto defrost, by heated cable as optional - Climate class 3 (25°C 60%Hr) regime M1 M1 product temperature -1/+5°C UNE-EN ISO 23953-2:2006 OPTIONS 40x60 runners per door

-

- Interior and exterior finish in plastic coated steel - Display area and counter in stainless steel AISI-304 - Smooth deck for display area, stepped at same price - 40 mm sides in injected ABS, excepd wood decor, two version available - Anodised aluminium profiles - Front rubber bumper - Tempered and hinged frost glass - Glass shelves non refrigerated - 40 Kg/m³ density polyurethane insulation, zero ODP and GWP - Ventilated evaporator - Ventilated condensation - Electronic temperature controller - External thermometer - Auto defrost, by heated cable as optional - Standard automatic evaporation - Climate class 3 (25°C 60%Hr) regime M1 M1 product temperature -1/+5°C UNE-EN ISO 23953-2:2006 OPTIONS 230v 60Hz / 115v 60Hz

-

- Interior and exterior finish in plastic coated steel

- Display area and counter in stainless steel AISI-304

- Plan of exposure for GN trays, maximum depth 65 mm (trays not included)

- Two versions of sides available in ABS injected, 40 mm thick

- Anodised aluminium profiles

- Front rubber bumper

- Toughened curved glass hinges forward, three versions available

- Standard lighting: top worktop and shelf

- 40 Kg/m³ density polyurethane insulation, low GWP and zero ODP effect

- Dry heating system

- Heated under storage with doors 440x270free

- Resistance silicone adhesive below the plane of exposure

- Electronic temperature controller

- External thermometer

- Working temperature +55°C +70°C

- Version flat botton at the same price.

-

- Interior and exterior finish in plastic coated steel

- Display area and counter in stainless steel AISI-304

- Plan of exposure for GN trays, maximum depth 65 mm (trays not included)

- Two versions of sides available in ABS injected, 40 mm thick

- Anodised aluminium profiles

- Front rubber bumper

- Toughened curved glass hinges forward, three versions available

- Standard lighting: top worktop and shelf

- 40 Kg/m³ density polyurethane insulation, low GWP and zero ODP effect

- Dry heating system

- Heated under storage with doors 440x270free

- Resistance silicone adhesive below the plane of exposure

- Electronic temperature controller

- External thermometer

- Working temperature +55°C +70°C

- Version flat bottom at the same price.

-

External finish in plastic coated steel, lacquered or stainless steel - Sides in ABS injected - Internal finish in AISI-304 18/10 stainless steel - Double glazed: front, sides and doors - Anodised aluminium profiles - Fixed glass shelves (height and tilt), with LED lighting - 40 Kg/m³ density polyurethane insulation, zero ODP and GWP - Ventilated evaporator - Auto defrost and automatic evaporation - Ventilated condensation - Electronic temperature controller - External thermometer - Climate class 3 (25°C 60%Hr) regime M1 VSS snacks refrigerated (+2°+8°) VSSB chocolate refrigerated (+14°+17°, 55% HR) All models can be customized in decoration All decorations are included on price, except glossy or melic finishing OPTIONS 230v 60Hz / 115v 60Hz

-

Stainless steel interior and exterior, rear side galvanized panel - Doors with self closing system, blocked opening, magnetic gasket and possibility of changing the opening sense - AISI-304 stainless steel worktop, with detachable white polyethylene table - Shelves made of plasticized steel wire, height adjustable - GN capacity in the worktop - AISI 304 stainless steel lid, isolated and hinged - Shelves made of plasticized steel wire, height adjustable - Castors as standard (2 with brakes + 2 without) - Fan assisted condenser unit - Fan assisted evaporator, with epoxi anticorrosion coating. - Automatic evaporation of defrost water - 40 Kg/m³ density polyurethane insulation, zero GWP and zero ODP effect - Digital temperature control, optimized defrost, high-temperature condensation alarm. Efficient management of energy consumption - Operating temperature 0°C +8°C , 38°C ambient OPTIONS stainless steel rear side 230v 60Hz / 115v 60Hz

-

A pre-engineered product range to cover the needs of the whole servery counter market! Counterline products range covers practically all your display needs and that includes:

- Drop-in Displays

- Free Standing Displays

- Countertop Displays

- Bespoke Counters

- Kitchen Fabrications

- and more!

-

The solutions A very wide range of built-in elements, with focus on the smallest details, designed to be used on load-bearing structures which you provide, based on your needs for functionality, appearance and visibility of the displayed products.

-

The flexibility A series of heated, refrigerated and neutral modular elements mounted on wheels that can easily be placed side-by-side. They can be positioned individually as islands or joined in line. The convenience of joining or separating the various modules lets you use Self 700 in all cases in which it is necessary to frequently change the distribution of the elements, for example in airports, train stations, highway dining facilities, etc.

-

SELF 800 is composed of a series of especially spacious self-supporting structure modules. All of the elements are designed to be easily joined in line. This lets you create self-service systems suitable for quick distribution of meals to a large number of diners (for example in dining facilities in companies, schools, military facilities, etc.).

-

The elegance A complete line of tops, wells, covers and display cases of the finest design for the display and distribution of foods, such as for breakfast or for a buffet.

-

Innovative, patented vacuum technology!

PALUX GreenVAC is the unique system solution when preparing and processing food without using bags. It is the perfect system to vacuum directly in gastronorm containers. Pressure sensitive products, e.g. berries, salad or mushrooms can also be vacuumed without product deformation.